A new research center on the Ford site in Cologne is focusing on the flexible and sustainable production of electric motors.

Green light for the HaPiPro² project: At Ford in Cologne, research will be carried out into how electric motors can be produced in a particularly sustainable way. Behind the research project is a consortium of Ford, thyssenkrupp System Engineering, RWTH Aachen University and Engiro. Together, their aim is to develop products and processes that will enable European manufacturers of electric vehicle components to assume a leading role worldwide.

"We are proud to host this pioneering research center at our Cologne site. The project will be a unique engineering platform for companies, especially with a view to researching and developing future production processes in the e-motor sector," says Gunnar Hermann, Chairman of the Management Board of Ford-Werke GmbH and Executive Director Business Transformation Ford of Germany.

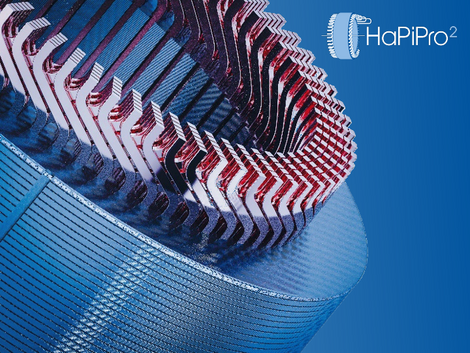

The name of the HaPiPro² research project refers to hairpin technology – a wire-winding method used in the manufacture of e-motors. The project participants will investigate how this method can be further developed to facilitate the manufacture of different e-motor variants on a single production line. The project is being supported with public funding to the tune of €5.3 million.